N TYPE PTFE THERMOCOUPLE WIRE

N TYPE PTFE THERMOCOUPLE WIRE Specification

- No Of Core

- 2 (Duplex)

- Conductor Type

- Solid or Stranded

- Cable Length

- As per requirement

- Temperature

- -200C to +125C

- Connector Type

- Bare Wire or custom connectors

- Product Type

- Thermocouple Wire

- Material

- PTFE (Polytetrafluoroethylene)

- Function

- Temperature Sensing and Measurement

- Usage

- Industrial Temperature Measurement and Control

- Voltage Surge

- Up to 600V

- Frequency (MHz)

- Low Frequency/Not Applicable

- Rated Voltage

- 300V

- Rated Current

- Depends on wire gauge

- Cable Capacity

- Standard Thermocouple Capacity

- Insulation Material

- PTFE

- Conductor Material

- Nickel-Chromium-Silicon Alloy (N Type)

- Length

- Available in custom lengths

- Size

- Standard and Custom Sizes

- Color

- Orange with white/colored tracer

- Diameter

- Standard (typically 0.2 mm to 1.0 mm depending on gauge)

- Application

- Process Control, Industrial, Laboratory

About N TYPE PTFE THERMOCOUPLE WIRE

Precision and Durability in Temperature Measurement

N TYPE PTFE Thermocouple Wire delivers reliable temperature sensing in harsh environments, thanks to its robust PTFE insulation and high dielectric strength. Its lead-free, flame-retardant jacket ensures safe operation even under extreme temperatures ranging from -200C to +125C. This cable is ideal for industries requiring accurate and consistent temperature control.

Versatile Applications Across Industries

This thermocouple wire meets ANSI/IEC standards and can be customized for length, size, and connectors, supporting broad industrial, process control, and laboratory applications. Its excellent chemical and humidity resistance make it perfect for corrosive settings, while its flexibility and tensile strength provide ease of installation and longevity.

FAQs of N TYPE PTFE THERMOCOUPLE WIRE:

Q: How is the N TYPE PTFE Thermocouple Wire typically installed in industrial environments?

A: Installation involves connecting bare wire ends to measurement devices or using custom connectors as needed. Its high flexibility and tensile strength make it easy to route through complex setups, and it can be cut to custom lengths to fit specific requirements.Q: What benefits does PTFE insulation provide for this thermocouple wire?

A: PTFE insulation ensures outstanding chemical and humidity resistance, high dielectric strength, and flame retardancy, safeguarding the wire against harsh substances and extreme temperatures, while maintaining flexibility and structural integrity.Q: Where can the N TYPE PTFE Thermocouple Wire be used?

A: It is suitable for process control, industrial temperature measurement, laboratory experimentation, and any application in harsh or corrosive environments, thanks to its robust chemical resistance and compliance with international standards.Q: What is the process for ordering custom sizes or lengths?

A: Customers can specify their required cable length and diameter when placing orders with the manufacturer or supplier. Options include both solid and stranded conductor types, and orders can be tailored with or without braided shielding to suit specific needs.Q: Why is flame retardancy important in thermocouple wire applications?

A: Flame retardancy minimizes fire risks in environments where high temperatures or electrical faults may occur, ensuring added safety for industrial and laboratory applications.Q: What kind of conductor is used in this thermocouple wire, and what is its advantage?

A: It uses a Nickel-Chromium-Silicon alloy conductor (N Type), known for stable and accurate temperature sensing across a broad temperature range and in corrosive conditions, making it ideal for industrial-grade usages.Q: Is the N TYPE PTFE Thermocouple Wire compliant with international standards and environmental regulations?

A: Yes, it complies with ANSI and IEC standards for thermocouples and is RoHS certified, meaning it is lead-free and suitable for environmentally conscious operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thermocouple Cables Category

Silicon Rubber Thermocouple Wire

Product Type : Silicon Rubber Thermocouple Wire

Usage : Industrial Heat Sensing, HighTemperature Applications

Color : Red, Yellow, Blue, or as per thermocouple standard

Material : Silicon Rubber

Function : Temperature Sensing and Transmission

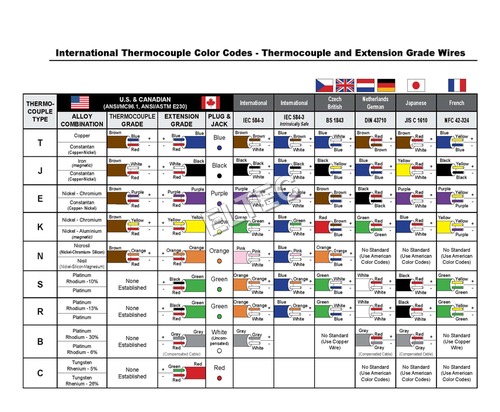

Thermocouple Wire color chart

Product Type : Thermocouple Wire

Usage : Connection of Thermocouples to Instruments

Color : As per ANSI/IEC Color Code (varies by type)

Material : Insulated Alloy Conductors

Function : Temperature Measurement

N TYPE CERAMIC THERMOCOUPLE WIRE

Minimum Order Quantity : 1 , , Meter

Product Type : N TYPE CERAMIC THERMOCOUPLE WIRE

Usage : Industrial

Color : Gray

Material : Aluminum

THERMOCOUPLE CABLE

Minimum Order Quantity : 100

Product Type : THERMOCOUPLE CABLES

Usage : Electronic Appliance

Function : Power Supply

Send Email

Send Email  Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese